Indoor lab

|

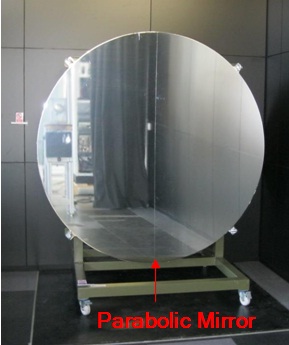

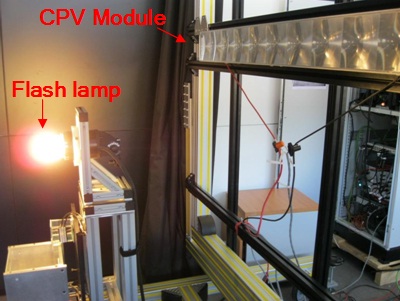

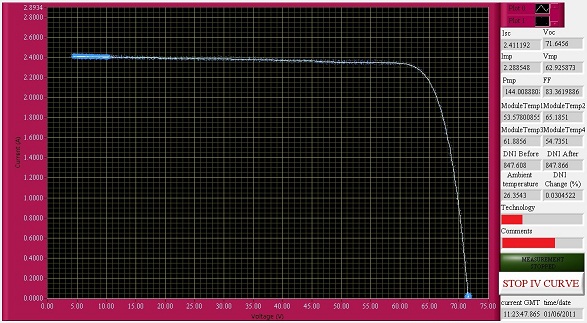

The CPV solar simulator at ISFOC serves a complete indoor characterisation of CPV modules, which has the special property of collimating the light rays in the angular range just like the rays coming from the real sun. A parabolic mirror is used in order to reach that requirement. The indoor characterisation involves, among other experimental possibilities: the complete module's I-V curve acquisition, power measurement and acceptance angle curve (angular transmission response of the CPV module) characterisation. This solar simulator is based on a pulsed flash lamp that reaches more than 1000 W/m2 during a few milliseconds, which is high enough to acquire the CPV module's photocurrent in each light pulse. A CPV reference irradiance sensor is previously calibrated outdoors; for its calibration, even spectral parameters for correlating indoor and outdoor conditions are monitored. The system is capable of measuring modules up to 400 volts and currents of up to 10A. The module's maximum active area is limited by the 2m diameter parabolic mirror.

|

Physicochemical lab

ISFOC has completely implanted this Lab in order to hold the test defined by the IEC 62108:2007, and UNE-EN 61215:2006, IEC 60068-2-21:2006 and ANSI/UL1703 as well. Meanwhile, a warehouse for test samples and another room devoted to different manual tasks, sample adaptation, and test preparation have been implemented as well.

As to assure quality and rigorous, reliable service, this lab's goal is to follow the UNE-EN ISO/IEC 17025 guidelines.

Through the Quality Certificate, tests or whatever other Lab activities carried out are guaranteed to comply with the corresponding standard or specification. The following tasks have been allocated to the certificate:

- Issued work instructions, procedures, and test methods.

- Lab Quality Manual

- Calibration tags on equipment

- Equipment Security Record

- Equipment Record (description and level)

- Test Record Database

- Equipment Manuals

- Calibration Database

- Uncertainty Estimation for testing

ISFOC available means for testing are listed below:

Climatic Chambers

Haul Launcher

Rain Test structure

Electric & Mechanical Tests

Climaters Chambers

|

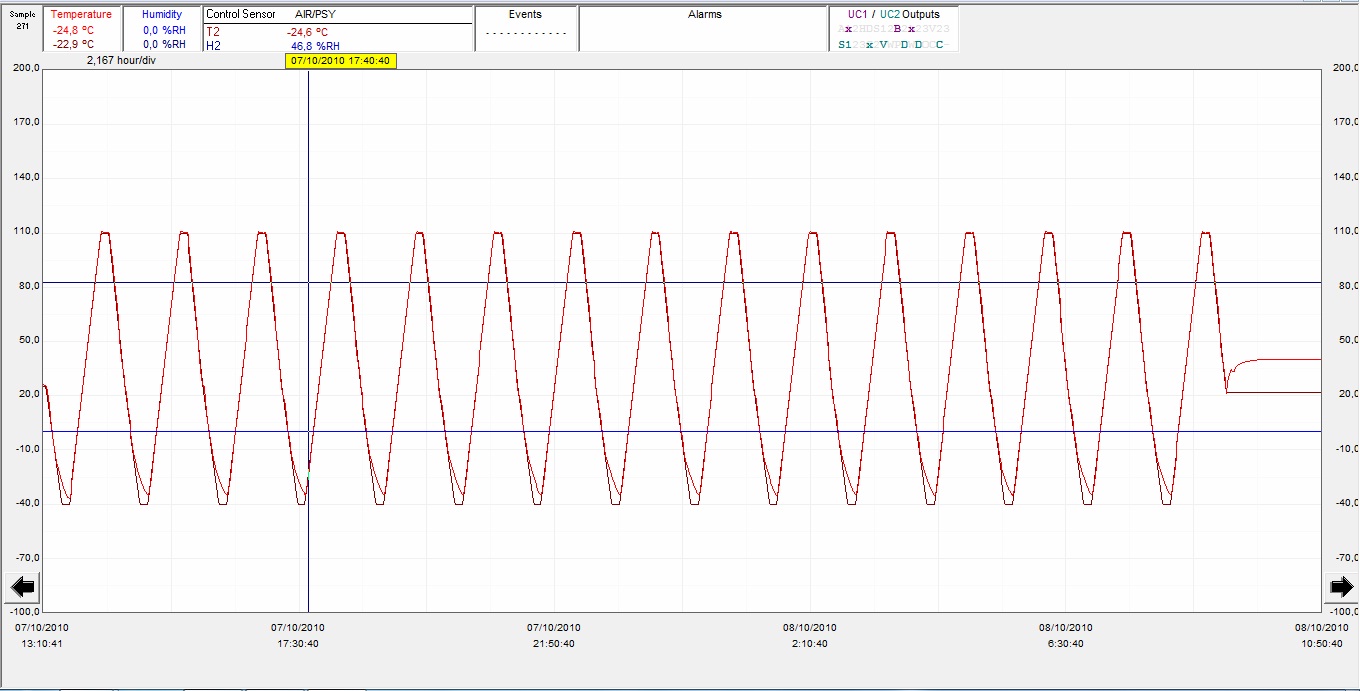

ISFOC has two climatic chambers and one UV light chamber. One of the climatic and UV light chambers are of large volume (8,000 litres), while the other climatic chamber only has a volume of 1,500 litres. This offers great diversity of sample size. These chambers also have an important feature: high speed in climatic ramps.

The tests performed by these chambers correspond to accelerated aging, from climatic tests with humidity to UV radiation, but mainly the tests indicated in the IEC standard 62108 for CPV modules are those such as "thermal cycle test," "humidity freeze," "damp heat," and UV exposure. Using the 3-chamber programming software, ISFOC can adapt itself to all the different needs of testing requirements, carrying out custom reports.

All three chambers are linked to the Solar Simulator, achieving degradations in the samples after the accelerated aging.

|

Hail Launcher

|

ISFOC owns a hail launcher, which simulates the possible weather conditions and includes a mould for the modelling hail. The test is held at 22 m/s (80 km/h) with as much impact over the sample as necessary.

|

Electric & Mechanical Tests

|

ISFOC’s different tools and equipment to hold the mechanical load test are listed below.

|

Rain Test

|

Rain test structure is made up of 3 taps with independent spray to 35 bar. This test helps to observe the module reaction when facing rain.

|

Outdoor Lab

Outdoor lab for CPV module characterisationAs a previous step to the analysis of CPV technology in plant operation, it is mandatory to know the different weather conditions. In that sense, ISFOC has developed full CPV module characterisation equipment, able to execute I-V curves over 8 modules simultaneously, by acquiring temperature data, radiation, or any other meteorological variable of interest. This equipment, all together with the SENER high-accuracy tracker, allows for carrying out studies of the different CPV module technologies, each outdoor measurement involved in IEC 62108, as well as calibrating mono-modules (reference sensors) so as to use them in the Solar Simulator. As ISFOC’s own design, this equipment is easy to improve and to be expanded upon, being a versatile tool for R&D task deployment.

|